TYPE-S

The secret behind comfortable and beautiful accordion pleats.

“TYPE-S” uses the Steam Stretch technique to create products that realize both functionality and beauty with the creases of their accordion pleats.

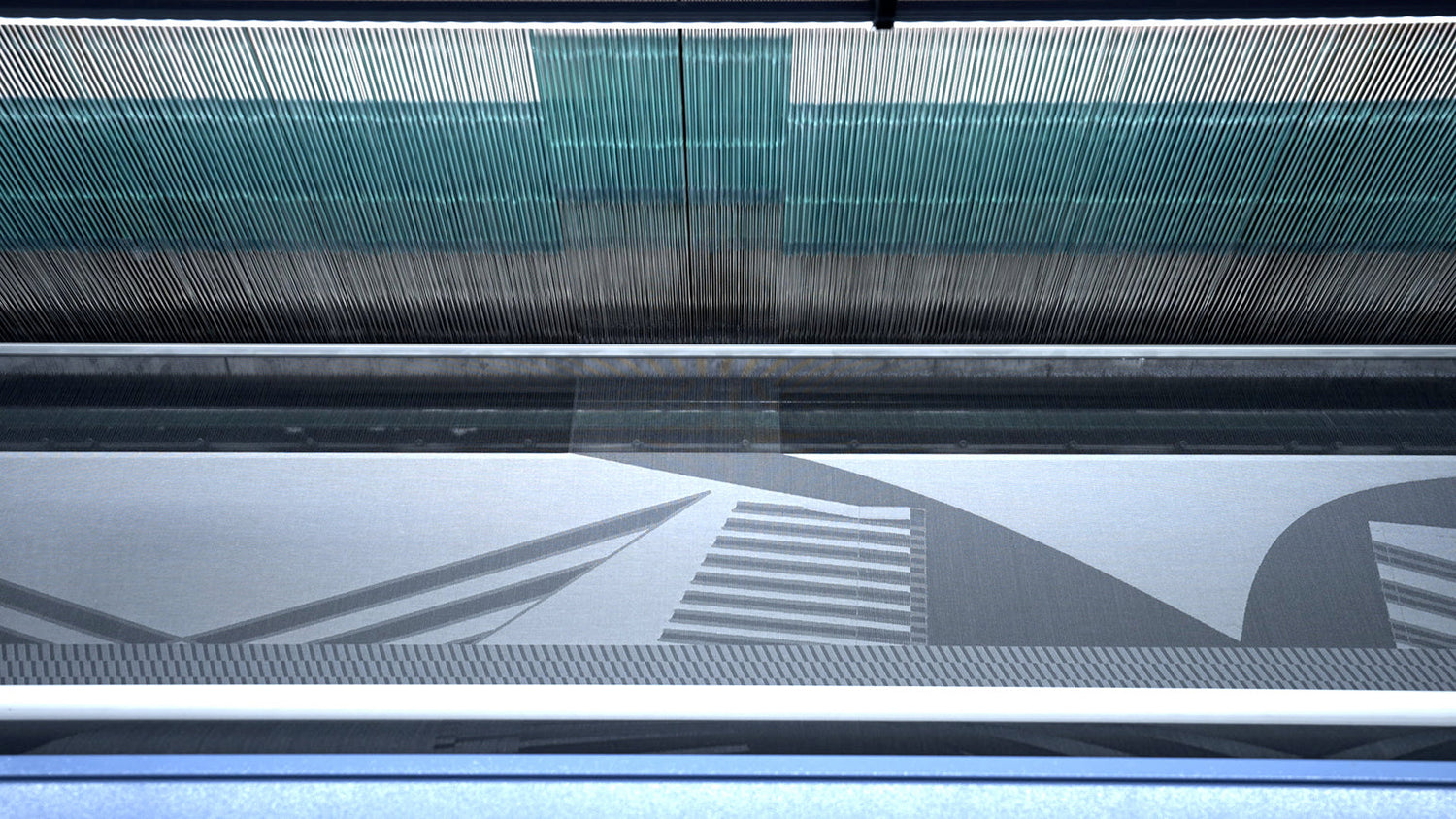

That’s why the basic process of making TYPE-S is similar to that of TYPE-O. A jacquard loom installed with a sophisticated program weaves the creases and patterns that eventually make the garments three-dimensional. Over 10,000 warp threads are controlled by the movements of a needle to plot out the parts of one garment in a single piece of cloth. Perhaps it's because the straight lines of the creases stand out, but the fabric holds a graphical and engineered beauty.

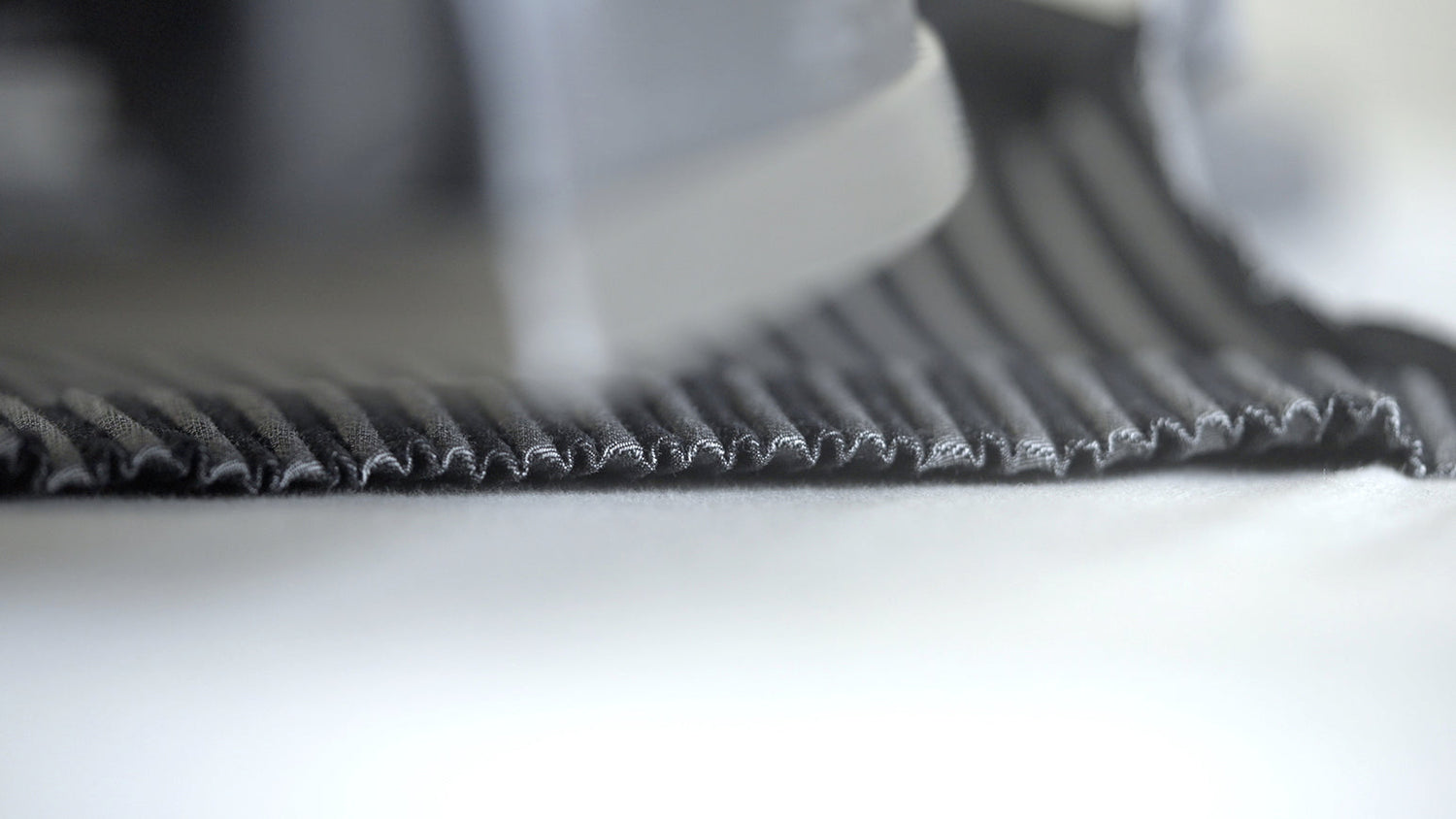

However, that is where the similarities in the clothes-making process ends. For TYPE-O, the parts that are cut out by scissors are set in a dedicated machine, where hot steam is applied all at once to create pleats (the fabric moves as if it were alive). For TYPE-S, the creases are created using an iron, steaming and pressing the cutout parts repeatedly. Because the movements are so efficient and rhythmical, the process may at first glance seem to be very simple, but there is a secret in the order in which the parts are ironed, the temperature of the steam, and how it is applied, giving a glimpse of the expert craftsmanship required.

Accordion pleats are made in the waist, around the knees, and other parts where the body moves. The graphical and beautiful design itself provides the functional elasticity of the garment. In other words, this is a design that is imbued with both beauty and functionality. Applying the engineering of Steam Stretch and discovering further new potential (ABLE) of clothing, this is how A-POC ABLE ISSEY MIYAKE’s clothes-making continues to expand.

Text: SETA SHO

This is a carousel of Image carousel: Article - A-POC ABLE ISSEY MIYAKE PRODUCT TYPES TYPE-S. Use pagination to navigate through the items.. Use Play Slide Autoplay Button to autoplay/pause the carousel.