TYPE-O

“No matter how many times you see it, you’re always amazed.”

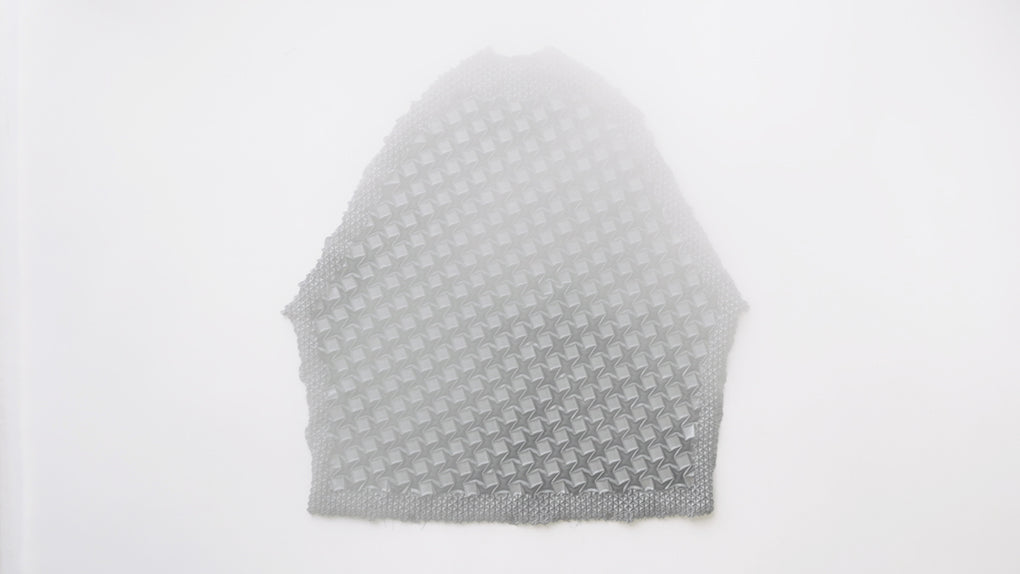

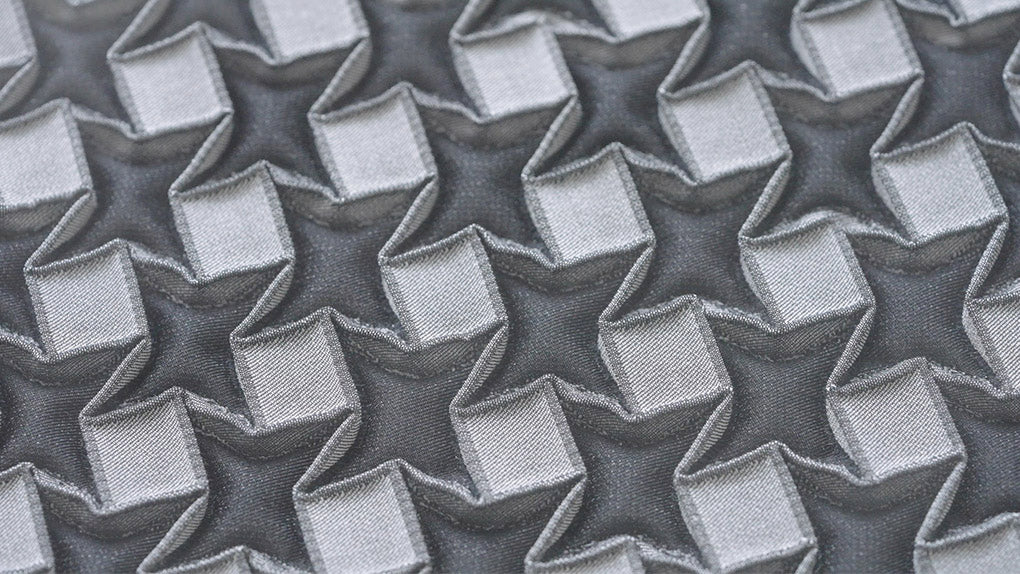

TYPE-O products are made through a completely different process than the standard pleats manufacturing. The original method uses a special program to weave and form three-dimensional pleats. In other words, it’s jacquard weaving! A data-programmed jacquard loom makes more than 10,000 warp threads go up and down, finely weaving the folds of pleats and contours of patterns into the cloth. The movements are like a beautiful dance, just as mellow and harmonious as an artisan’s handiwork.

The single piece of cloth that is created (with all the parts for a single garment already woven in) is cut with scissors and processed with hot steam. If there is a high point in this movie, it would definitely be this process. The switch is flipped on, steam gushes out, and the cloth instantly shrinks tightly. Switch on! Steam! Shrink! The cloth shrinks along the folds of the numerous undulations woven into it, instantly transforming the smooth cloth into a three-dimensional pleated garment. It almost seems like a fantastical living creature with a mind of its own, but it is actually something created through the evolution of this particular technology. Various materials are used as a base and by weaving in thread that shrinks with heat and controlling the degree of shrinkage, the garments are commercialized as products.

In other words, it is like a single thread has a will of its own. A-POC ABLE explores a piece of cloth by transforming the process of clothes-making and forming various new ideas (ABLE). Enjoy this behind-the-scenes look at A-POC ABLE ISSEY MIYAKE’s clothes-making.

Text: SETA SHO

This is a carousel of Image carousel: Article - A-POC ABLE ISSEY MIYAKE PRODUCT TYPES TYPE-O. Use pagination to navigate through the items.. Use Play Slide Autoplay Button to autoplay/pause the carousel.