LIGHTLY SPRINKLED – The making of KYO CHIJIMI FRIKAKE

Dots and sprays.

Sprinkles and scatters.

Warm steam, river breezes.

And slowly, abstractions take shape on textile surfaces – irregular and unique, imbued with a free and joyful beauty.

It’s a humid summer morning in Kyoto. A master artisan, plastic gloves on hands, is flicking a wet brush with a metal tool – fluidly, lightly, rhythmically – each motion expertly spraying a scattering of liquid dots onto textiles laid out on newspapers. Steam rises silently from industrial machines, while a soft breeze from nearby Katsura River flows through the open factory space, causing pattern-sprinkled clothing drying on railings to sway gently.

This is the timeless setting for the making of KYO CHIJIMI FRIKAKE, a new series of clothing hand-dyed by Kyoto artisans for HaaT. The creations are inspired by frikake – a much-loved everyday Japanese seasoning sprinkled lightly on rice, made from tiny fragments of dried fish, seaweed, and sesame seeds. The FRIKAKE series reflects these scattered seasonings, through its abstract dotted and sprayed textile surfaces – an effect rooted in an innovative take on a traditional discharge dyeing technique, brought to life in the practiced hands of Kyoto artisans with decades of expertise. Unusually, artisans in the southern Kyoto factory carry out every step of the dyeing process in-house – from dyeing and steaming to drying – ensuring the highest quality production while leaving space for progressive innovation. The starting point is, as always, the textile. The new series uses Kyo Chijimi – lightweight and crafted, slightly crinkly and breathable, the Kyoto material has long been perfect for hot summer weather.

Artisans first lay out garments on newspapers before placing tape on the border areas of the textile that will resist dying. And then the flicking begins. Key to the process is the use of a traditional liquid glue, made from an organic mix containing sulphur. Artisans dip a large brush into the glue and, with expert sharpness, flick it rhythmically onto a perforated metal tool – causing the liquid to spray in confetti-like scatters across the textile surface. The clothing is hung up to dry on railings, the sprayed spots of discharge glue slowly disappearing – fresh river breezes flowing through the factory space adding a hint of nature to the dyeing process. Next, the clothing is steamed in a walk-in machine, with the glue-sprayed elements of the textile slowly shifting into focus as white dots, before hanging out to dry. And then the cycle continues, as artisans begin flicking again, this time layering other color dyes onto the same textiles, before drying and steaming and drying once more.

The creative process is a modern riff on traditional Japan. The methods are rooted in old techniques long used by obi makers, kimono dyers and painters, who typically used bamboo tools to wrist-flick glues, dyes, inks and paints – particularly when evoking atmospheric natural scenes, from snowfall to misty skies. For FRIKAKE, the artisans’ movements seem still, even, measured – yet the process hovers perfectly along the fine line between masterly control and wild beauty. The end result? Surface scatterings imbued with a spirit of freedom and joyful spontaneity. Meanwhile, imperfections meld into the creative process. Light bleeding irregularly occurs along the taped lines. The outcome is further impacted by humidity levels in different seasons of the year. Artisans balance technical expertise without being overly controlling – instead, embracing the edges of imperfection more typically found in the natural world. These artisans are unwavering masters of their dyeing skills not only through their actions, but also by knowing when to surrender to elements of the process beyond human control – as perfectly embodied by the scattered beauty of the FRIKAKE series.

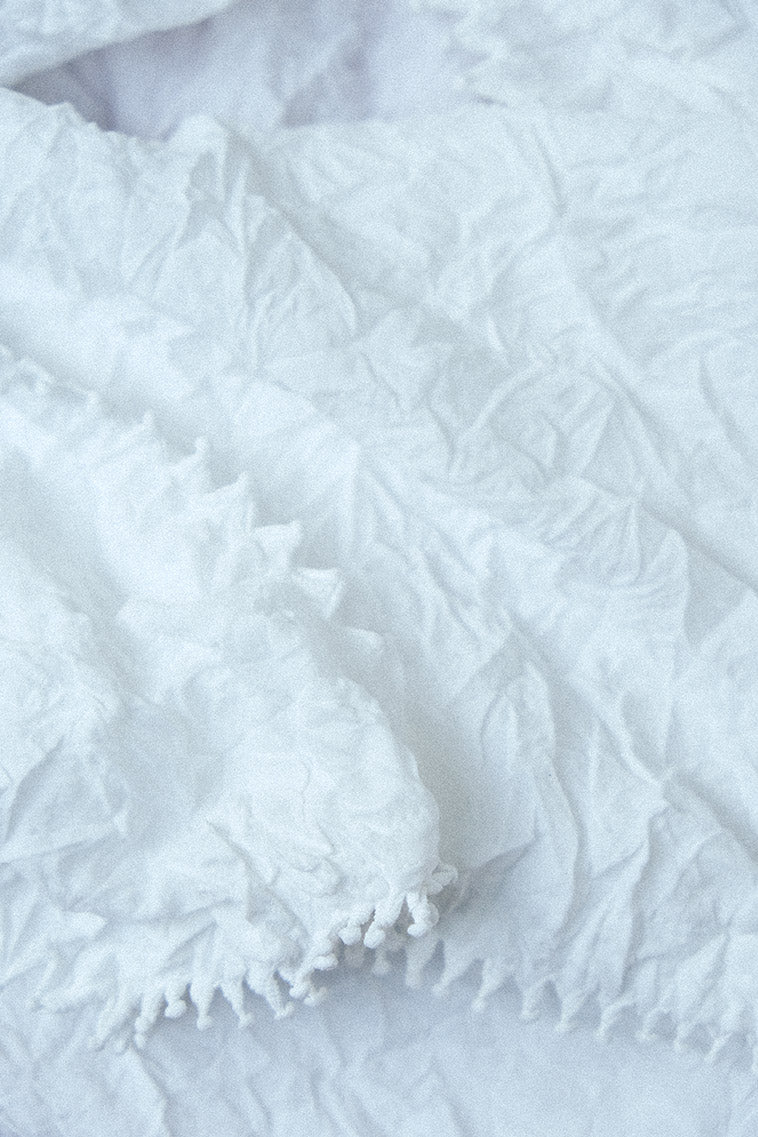

KUMOSHIBORI

Arimatsu-shibori is the general term for the cotton shibori (tie-dyeing) conducted in the Arimatsu-cho and Narumi-cho areas of Nagoya City, Aichi Prefecture. It began and flourished in the early Edo period (1603-1867), when shibori hand towels and other such items were sold as souvenirs to travelers on the Tokaido Highway. Since then, Arimatsu-shibori has been mass-produced in more than 100 different types of shibori patterns using various methods such as tying, sewing, and binding the cloth. Kumo-shibori, one of these patterns, is known as the most common tie-dye design.

For Kumo-shibori, part of the cloth is tied by hand and dyed. After dyeing, the tied part is untied and a spiderweb pattern is revealed (kumo means spider in Japanese ). However, HaaT focuses on the shibori in its tied state, and aims to make the beautiful, organic form of the shibori be remembered in the garments. Created based on this aim, the KUMOSHIBORI series applies the shape-memory property of polyester and incorporates the bumps of the shibori into the design.

KUMOSHIBORI has now become a staple HaaT series. We have continued to use the small Kumo-shibori bumps to add charming decoration to the neck areas and hems of clothing.